Examples |

||

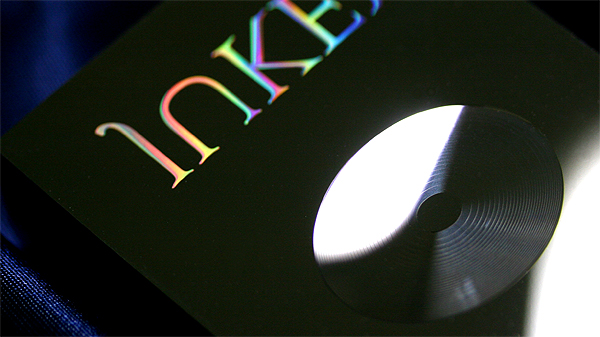

1. Ultra Precision Lathe Cutting |

||

|

|

|

There is no essential difference from regular lathe cut, except for its precision. With nano order machining, efficient optical surface can be machined such as spherical lens (convex and concave), aspherical lens, fresnel lens, toroidal aspherical lens, and so forth. (Left: Toroidal aspherical lens master / Right: Spherical lens mold insert x1000) |

||

2. Ultra Precision Milling |

||

|

|

|

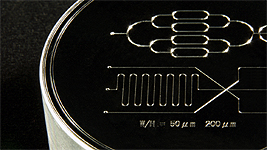

Ultra precision milling give us wide range of applications not only optics but also bio field, medical application and decorative elements. (Left: micro fluidic device master (channel width 50µm and 200µm) / Right: magnified image)

|

||

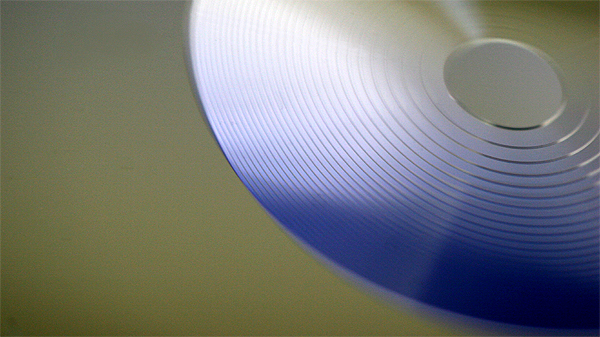

3. Ultra Precision Shaving |

||

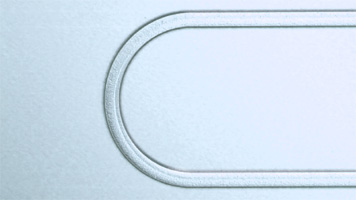

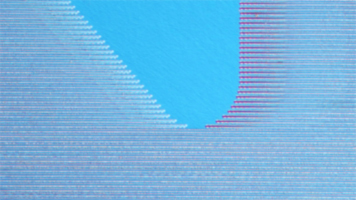

Diffraction grating was created by shaving cut. This type of products can be applied to light source, special functioning optical elements, and medical applications etc. Besides scientific application, this is also applicable to engraving. (These are not computer graphics) (Upper left: engraved by diffracting grating pattern. / Upper right: magnified) (Lower left: V shape groove 2µm width / Lower right: V shape groove magnified) |

||

|

|

|

|

|

|

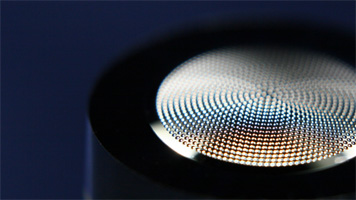

4. Multi-ax Machining |

||

Multi axe simultaneous control can open doors to many of you who wants to create a component that never exist. This is a great chance to create new products and let us help you.

(Upper left: spherical surface with micro lens array / Upper right: magnified image) (Lower left: toroidal aspherical fresnel lens / Lower right: magnified image) |

||

|

|

|

|

|

|

Contact

日本語